WS-D1 flat position sensor

WS-D1 flat bar sensor

WS-D1 flat position sensor

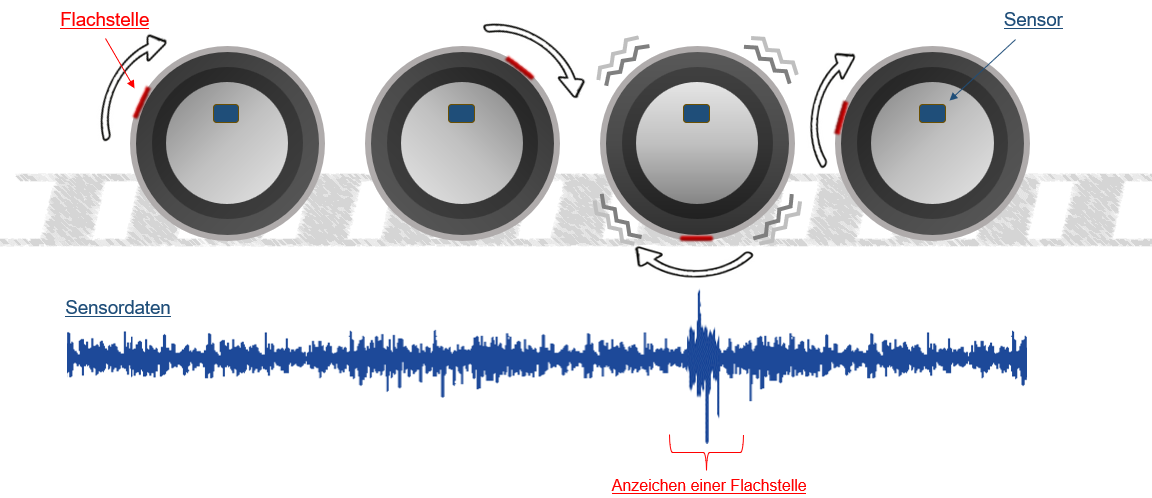

Timely detection of flat spots on the wheelsets of a rail car is critical to the safety and reliable operation of the rail transportation system. Flat spots can be caused by permanent deformation of the wheel arch and lead to uneven wear of the rails, damage to the track material and increased noise levels during travel. A radio sensor is used to detect and eliminate such flat spots at an early stage. This continuously monitors the condition of the wheels during transport and reports irregularities.

Functionality of the wireless sensor:

The radio sensor is a wireless, autonomous device that is mounted on the bogie’s anti-lift device. It uses innovative sensor technologies to detect the vibrations and shocks of the wheelset. The collected data is checked for irregularities by the sensor itself using a special algorithm.

Data processing, analysis and algorithm:

Once the wireless sensor is in operation, it starts collecting vibration data from the wheelsets of the railcar during transport. These data are processed in the sensor. The sensor’s model is trained to identify flat spots by detecting characteristic patterns of irregularities associated with that condition.

Alerting and notification:

When the algorithm detects a potential flat spot, the wireless sensor triggers an alarm message. An immediate notification is transmitted to your portal via the connected telematics basic device and sent by e-mail message to a relevant group of people.

The alarm message contains information about the detected potential flat spot, the car number and time stamp, and the location of the shipment where the signs of a flat spot were detected.

Assembly

We will support you with the installation and are happy to answer any questions you may have.

Mounting bracket for attachment to the anti-lift device. (D00529).

Mounting plate for gluing and clipping to the bogie frame (D00288).

benefits

of the wireless sensor flat detection:

Early detection: Continuous monitoring allows flat spots to be detected at an early stage, even before they assume critical proportions and cause serious damage.

Increasing safety: Early detection of flat spots contributes to the safety of rail traffic by preventing accidents and damage to the infrastructure.

Preventive maintenance: With the information from the wireless sensor, maintenance personnel can take the necessary measures in a targeted and efficient manner to remedy the flat spots and prevent consequential damage.

Localization of the culprit: By constantly monitoring the wheelsets during each transport, when a flat spot is detected, the area from which the flat spot was detected in the transport can be localized. The data can help to locate the originator of the flat spot.

technology

Power supply: lithium battery.

Motion Detection: 3 axis acceleration sensor.

Antennas: integrated short-range radio antenna.

Radio standard: 2.4 GHz, “ITSS IF2 Ready”.

Housing dimensions: L 65 x W 50 x H 36 [mm].

Operating temperature: -40°C to +80°C.

Weight: approx. 150 g / 430 g (without / with mounting bracket).

Degree of protection: IP69, acc. DIN EN 60529 through full encapsulation.

Certification: Railway applications acc. DIN EN 50121-3-2, DIN EN 50155, DIN EN 61373 (Cat. 3), CE conformity.

Variants: D00288 (mounting on bogie frame) // D00529 (mounting on lift-off safety device).

Do you have questions?

office

Rheinische Strasse 171

44147 Dortmund

Give us a call

+49 231 444 704 -0